2026-01-08

PFAS-Free Ceramic Membranes: Europe’s 2026 Water Treatment Answer

Per- and polyfluoroalkyl substances (PFAS) have emerged as one of the most pressing regulatory challenges confronting the global water industry. Thanks to their extreme persistence, resistance to degradation, and long-term health risks, PFAS are no longer regulated as conventional contaminants—they’re being treated as structural environmental hazards. In Europe, this shift has culminated in the revised Drinking Water Directive (EU) 2020/2184, set to fully take effect in January 2026.

Under this directive, drinking water supplied to consumers must meet ultra-low PFAS limits: a maximum concentration of 0.50 μg/L for total PFAS, and 0.10 μg/L for the sum of priority PFAS compounds like PFOA. These thresholds apply across all EU Member States and are enforced at the point of consumption. More critically, the regulation reflects a broader policy ethos: long-term compliance won’t just be measured by water quality outcomes—it will require responsible material selection and source-level risk elimination.

As a result, PFAS-containing materials used in water treatment processes are facing heightened scrutiny. Polymeric membranes based on PVDF, long hailed as an industry standard, are now structurally disadvantaged under the new regulatory framework. While cost-effective and widely deployed, PVDF membranes offer limited PFAS removal efficiency at ultra-low concentrations—and they’re classified as part of the PFAS family themselves. This creates inherent regulatory uncertainty, positioning such systems as transitional stopgaps rather than future-proof solutions.

Meanwhile, water utilities and industrial operators are grappling with soaring compliance costs, mandatory PFAS monitoring requirements, and pressure to align with EU sustainability funding criteria. These forces are accelerating the shift toward PFAS-free treatment technologies that deliver reliable performance while minimizing long-term regulatory risk and total life-cycle costs.

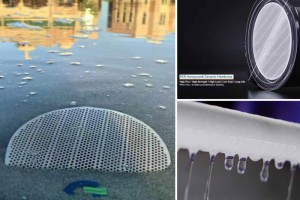

Ceramic membrane technology is increasingly recognized as a robust answer to these challenges. Manufactured from inorganic materials like alumina and titania, ceramic membranes are 100% PFAS-free—fully aligned with current and anticipated EU regulatory demands. Their high chemical and mechanical stability enables consistent PFAS removal even under harsh operating conditions, while their simplified process design cuts down on system complexity.

While ceramic membranes typically require a higher upfront investment, their long service life, fouling resistance, and stable operation translate to significantly lower total CAPEX and OPEX over the full system lifecycle. What’s more, their durability and recyclability support sustainability goals and long-term infrastructure resilience.

As Europe marches toward a PFAS-regulated future, water treatment strategies are being redefined. Technologies reliant on PFAS-based materials face growing limitations, while PFAS-free ceramic membranes are emerging as a mature, reliable, and future-ready foundation for compliant water treatment systems.

.jpg)